From 1846 when the Vineyard Gazette was founded by Edgar Marchant until 1920 the paper was printed from movable types, first invented in China in some unestablished background of the past, and invented independently by Gutenberg in Europe in the mid-15th Century.

Typesetting was accomplished in this way. Compositors or typesetters stood or sat on tall stools in front of compartmented cases in which type characters representing different letters were conveniently kept. The small “e” was the most frequently used type, and therefore it had the largest and most accessible compartment. “Lower case” came to be the phrase describing small letters, for they were nearer to the typesetter . “Upper case” or capital letters were above.

Swiftly moving fingers picked out the letters - in the form of individual types which had come originally from a type foundry - and composed them to follow in order word by word, space by space, and sentence by sentence, the “copy” which was the appear in the newspaper. If an intended line of type did not fill out its space completely - or was not “justified” - the compositor deftly inserted whatever space might be required.

The type set by individual compositors was assembled into complete stories on long trays or galleys. A sponge was kept handy with which to wet the type so that the individual letters would stick together and the risk of spilling or dropping out - a great risk where so many small bits of metal were involved - was minimized. Each galley of type was inked with a hand roller and a strip of paper taken on a proof press operated by a hand lever.

The chance of errors, even with skilled composers, was great. These were corrected by hand, and type was then transferred into column lengths, defined and held by brass column rules, until whole pages were ready for printing the next edition of the paper. The page forms were locked by means of printer’ quoins - double wedges - in iron frames or chases.

Tedious Methods

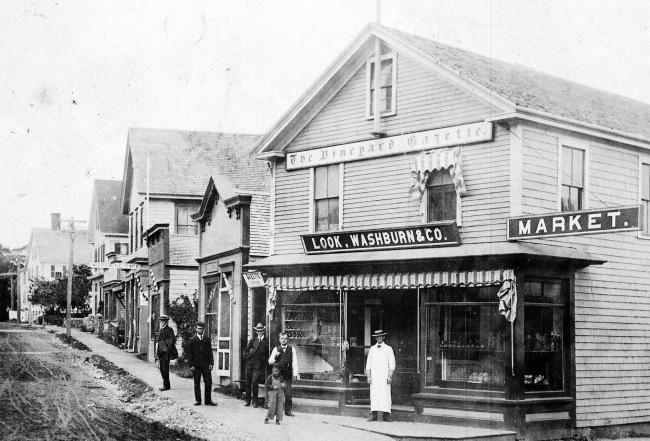

The Gazette first used, beginning in 1846, a hand press pretty much like Benjamin Franklin’s but showing the advance from wood into the iron age. The locked up chase representing a page of the paper had to be put upon the bed of the press. Inking with a hand roller was done by a boy who also supplied a sheet of paper, and the press lever was pulled by a strong printer to make a single impression - one page at a time.

To print reverse sides of pages, the process had to be repeated.

And after the edition was printed, ink was washed from the type pages with kerosene and all the individual pieces of type had to be distributed into the cases before the typesetting for the next issue could be begun.

The Gazette’s first departure from these tedious methods came in the matter of a press. The flat bed hand press was not used over a long period before a more ambitious machine was installed, a Fairhaven two-revolution press turned by a hand crank. The type forms were placed up on a flat bed, but now there was room for four pages. Inking was no longer by hand but by means of rollers which moved with the operation of the press and transferred ink from a trough or fountain which occupied its full width.

Sheets of paper were fed from above, to pass around a cylinder of such a diameter that in two revolutions the whole sheet of paper would have been brought in contact with the type pages. Some earlier presses had an enormous cylinder - a drum cylinder it was called - so that a single revolution would suffice. But the two revolution press was an advance. After the sheet of paper had been printed through the action of the cylinder against the inked type, the sheet of paper was seized by grippers and carried to a delivery pile at the rear. This method of transferring sheets was known as a butterfly delivery, and unless the grippers were timed with complete accuracy they would drop a sheet upon the forms where it would be ground to tatters before the press could be stopped.

The First Linotype

The old Fairhaven - so named because it was made in Fairhaven - was superseded in the early 1920s by a Whitlock press operating on precisely the same principle but by means of an electric motor. The press bed was larger accommodating larger pages; but sheets were still fed by hand twice over, once for each side.

In 1920 the Gazette acquired its first Linotype, a version of the machine invented by Ottmar Mergenthaer in 1885. Here was a new principle which superseded almost entirely the movable types of Gutenberg. Foundry cast type was no longer needed. The Linotype was equipped with a metal pot or crucible in which type metal - an alloy of lead, tin, and antimony - was kept fluid by an electric heater at a narrowly controlled temperature.

The front of the machine presented a keyboard, analogous to but entirely different from that of a typewriter. When the operator touched the key representing a letter or character, a matrix of the desired character and of the correct width, was released from a magazine above, and allowed to drop through a channel until it reached an assembly carriage at the operator’s left.

One by one the matrices dropped and the operator, noting the completion or near-completion of his desired line, used a simple lifting motion to send the assembled line of matrices to jaws where the line was held for casting. The necessary spacing to fill out incomplete lines was accomplished automatically by spacebands - on the principle of wedges - forced up between the groups of matrices representing words.

Casting of lines of type was accomplished by the descent of a plunger into the metal pot, forcing sufficient metal through a mouthpiece against the line of justified matrices. The completed lines dropped into a delivery galley and the matrices were lifted by a elevator arm to be distributed automatically into the magazine channels from which they had come. The matrices for each letter bore a distinctive combination of teeth, assuring that they would drop into the correct channel and no other.

The operation of the machine was simpler than an explanation. What was brought about by the principle of the circulating matrix was the capacity for selecting and casting type characters, a line at a time in unlimited quantity (so long as the metal supply held out) and eliminating the tedious distribution of individual types, since the Linotype slugs or lines were simply melted up after each edition of the paper and used over and over again.

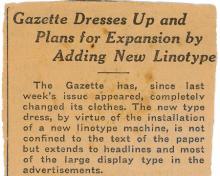

Many improvements through the years made the Linotype more useful and flexible. Display type up to the size of normal headlines could be set from the keyboard, and automatic quadding and spacing devices simplified the work of the operator still more. If a line, for instance, was to contain a single word, modern Linotype would instantly introduce the extra spacing; and words could be set at one end of a line or the other by a simple motion of the operator.

1929: The Duplex

Large display type, the matrices of which were too heavy to run successfully through the circulating system of the Linotype, came to be cast on a Ludlow machine. The matrices here were assembled by hand, and distributed by hand after the casting. But with matrices of large size the distribution would be managed pretty easily.

In 1929 the Gazette discarded is old Whitlock press and installed a Duplex web perfecting press, still printing from flat forms - made up of Linotype lines or slugs mostly - but using roll paper so that there was no more hand-feeding of sheets. The moving web of paper, entering the press at one end, passed over the forms for as many as four pages on a lower bed, and then across four more on an upper bed, completing the printing of both sides of the paper as many as eight pages in all - through a single operation. The web of paper entered continuously and emerged continuously through cutting and folding rollers to yield complete copies of the edition; but it was held momentarily while the impressions were being made, the slack at these moments being taken up by means of an equalizing device.

The theoretical speed of the Duplex was some 3,000 eight page papers an hour, as against the slow hand-feeding of sheets at a fraction of this speed on the old presses. In 1940, say, the Duplex was serving admirably, for the circulation of the Gazette was about 3,000 copies a week, a great advance over the total press run of 600 in 1920. But in 1974, with press runs exceeding 11,000 copies, and with editions of 16 or 24 pages or more, the old press was being sorely taxed.

Comments